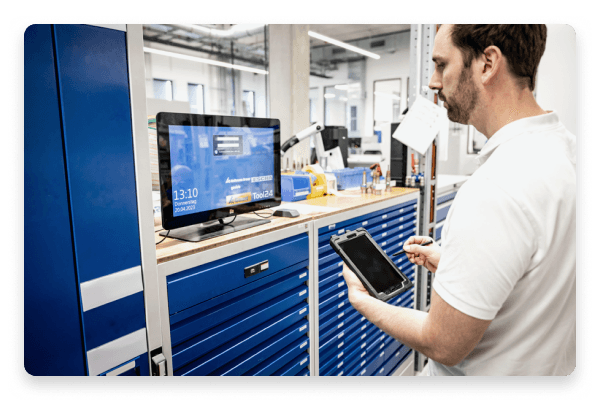

Capture tool data seamlessly

Ensure full transparency

Visualize the complete usage history of your milling tools and draw the right conclusions from the work results.

Optimize tool data

For example, adjust the cutting values of your tools and improve your processes.

Specify post calculation

Find out exactly which tools have run for how long on which position and improve your post-calculation.

New data, more possibilities. Every tool has its own history. It's good to know it and learn from it for the future.

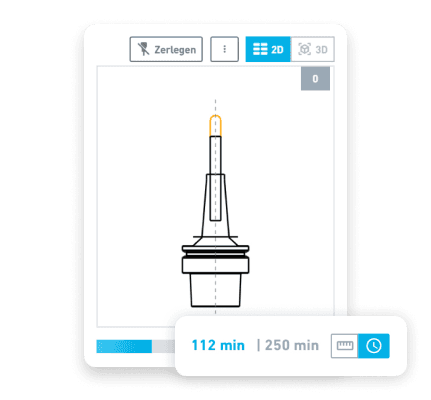

Benefit from better visualization

Capture the complete usage history of a milling tool at a glance.

Determine wear based on data

The tool usage can be displayed both in time and in meters in operation. This allows you to determine the actual wear much more accurately in the future.

Gain more insight thanks to integrations

In connection with the MES and MECS, you also record the complete order context. How was the tool used? For which specific workpiece?

Accelerate inventory

A relief when the annoying tasks are done faster: get an overview of all your physically available tools, e.g. for an inventory optimization.

EVOMECS means future viability

What potential lies dormant in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.