Control and monitor production

Increase responsiveness

With EVOMECS, your managers always know what is going on and can react ad hoc to planned and unplanned events.

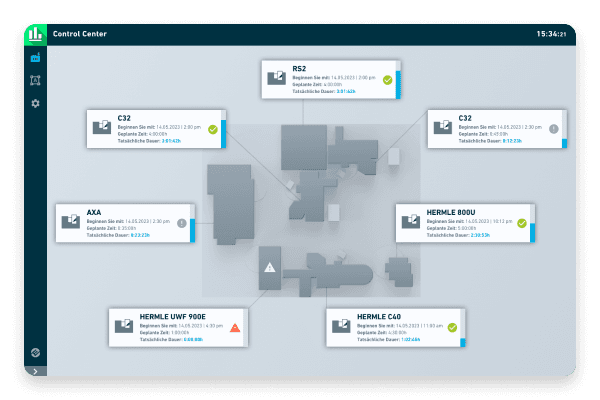

Enable real-time insights

Maintain a complete overview of the status of your production at any time.

Create clarity about the worklist

Employees who have all the information they need at their fingertips can concentrate better on what's important - their work on the shop floor.

Consistent workflows significantly increase productivity and quality in manufacturing.

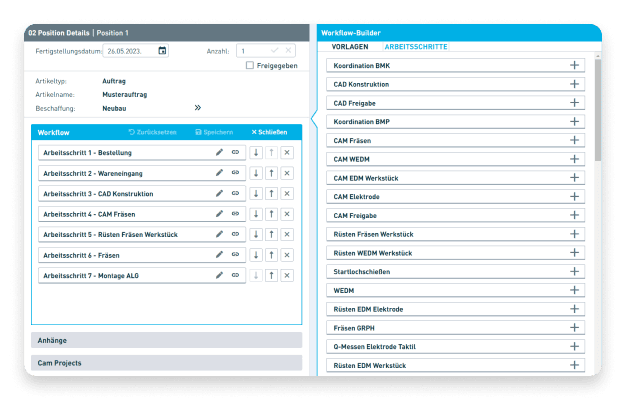

Customizable templates for your workflows

Custom Manufacturing: create workflows that match your exact needs and processes to simplify day-to-day use.

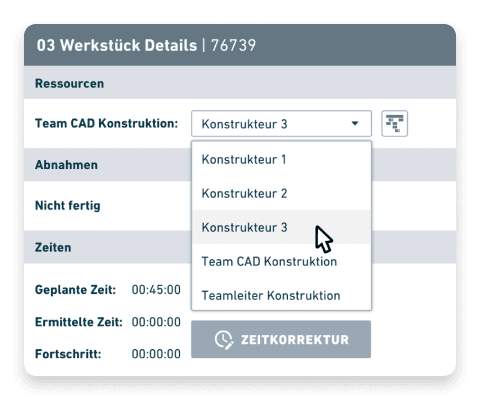

Targeted utilization control

Assign tasks from workflows, resource pools, or individual resources to optimize the utilization of your staff and machines.

Conveniently manage attachments

Use digital advantages cleverly: attach as many documents as you like to the work steps, which your employees can access digitally at their workstations at any time.

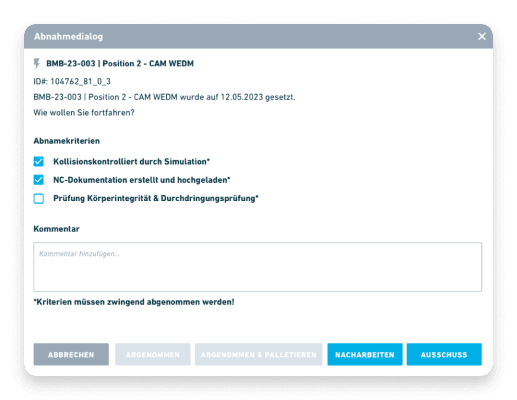

Strengthening quality assurance digitally

Ensure consistently high quality of your products by digitally storing individual acceptance criteria for critical work steps.

Optimize manufacturing based on your data

Now that you are capturing data in real time and monitoring it via the configurable control center, you can also use this knowledge for your manufacturing analyses in the future.

EVOMECS means future viability

What potential lies inactive in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.