Track workpieces seamlessly

Reduce search times, increase productivity

He who seeks, finds. Eventually. With EVOMECS, no one has to search: each workpiece is assigned to a fixed storage location. This brings order and productivity to any production.

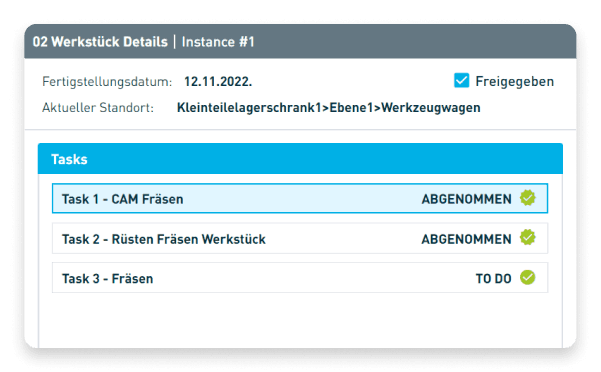

Consistently map the production history

In the future, you will be able to track the creation of every workpiece seamlessly and in real time. You get a continuous view of all information and improving your documentation.

360-degree view of manufacturing

Benefit from consistency: in conjunction with EVOMECS Toolmanagement, our MES also records all data on the milling tools used.

Be faster and get better. Seamless individual workpiece tracking not only saves considerable time, but also improves the quality of your products.

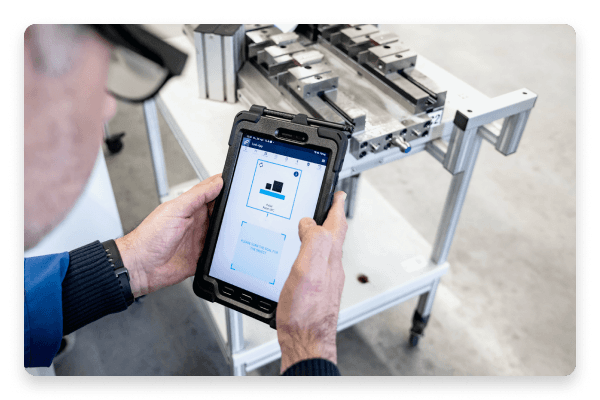

Identify workpieces more easily

Workpieces are identified using any system, such as DataMatrix. A standard smartphone is sufficient for scanning the workpieces and assigning the storage locations.

Knowing what's up

You can see the machining progress of each workpiece in real time in our MES. The customer can be informed about the status of his order at any time if required.

New data, new business opportunities

The complete production history provides new data and thus valuable information for digital analyses and forecasts. Use this potential for your business growth.

EVOMECS means future viability

What potential lies inactive in your production? With our ROI calculator, you can individually calculate the savings potential through the use of the EVOMECS software suite using various scenarios as examples.